Value Delivered

Forest Electric New Jersey (Forest NJ) met the client’s fast-tracked schedule by working multiple shifts, seven days a week. To help facilitate a lean, efficient project with multiple trades working together, we produced electrical materials in-house at our prefabrication shop. Our prefabrication team spooled out, bundled, and pre-terminated all Cat 6 cable runs, as well as cut to size and terminated all fiber cable.

Client Objectives

The client needed to relocate their campus data center to a more central location to accommodate forthcoming new buildings.

Scope of Services

Forest NJ’s services included:

- Furnishing and installing 220 cabinets in three data center pods

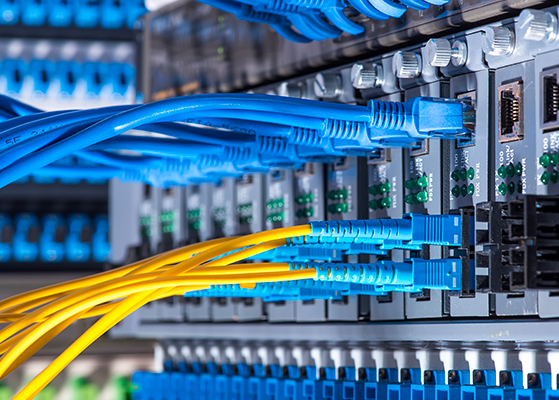

- Providing pre-terminated multi-fiber push-on (MTP) fiber and copper cabling

- Installing 800,000 feet of Cat 6 cable—48 cables from a redundant source for each cabinet

- Installing 40,000 feet of 12-Strand MTP fiber cables—two cables from a redundant source

Client Background

The client is a global biopharmaceutical company headquartered in New York that manufactures prescription pharmaceuticals and biologics.